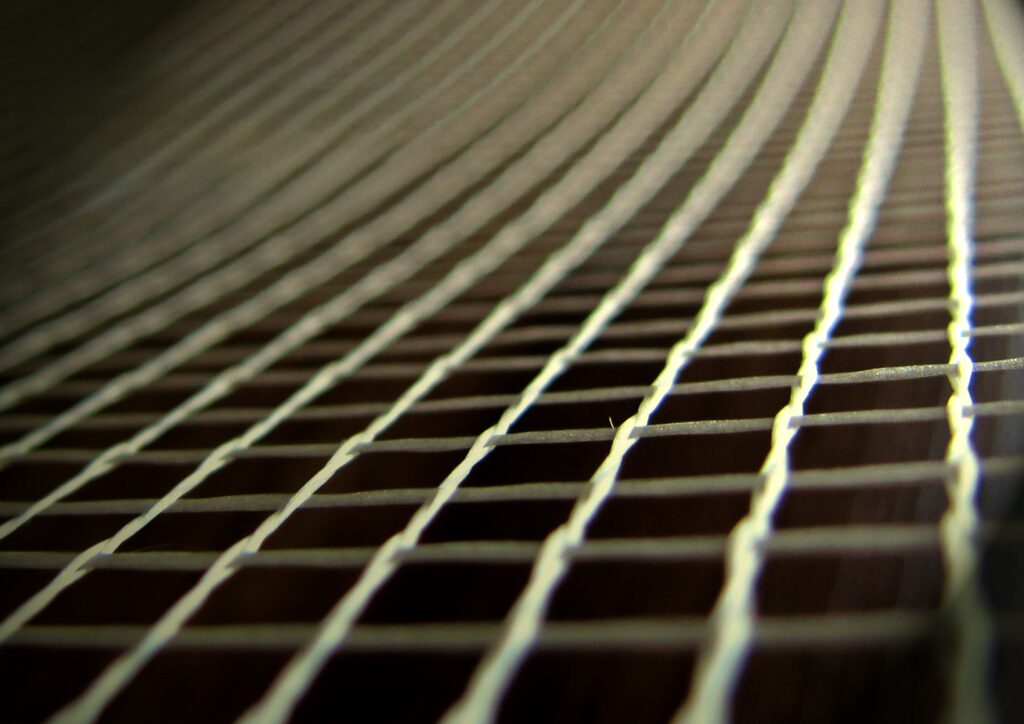

Using protective mesh as a reinforcing and protective layer at wall intersections and at connection points of walls to structural elements is of great importance. This mesh increases the strength and durability of finishing materials and prevents cracks caused by various stresses. Additionally, protective mesh effectively safeguards installations and equipment embedded in walls, especially in areas prone to damage or infiltration of foreign materials. This practice is recommended according to relevant construction codes and publications to significantly enhance the performance and safety of structures. Installing protective mesh not only improves strength but also extends the service life of buildings.

Applying protective mesh at wall intersections and structural element connections significantly boosts the strength of these joints. It ensures uniform distribution of forces and prevents cracks and potential damage in walls.

A key application of protective mesh is protecting installations and piping inside walls. Besides providing insulation, the mesh prevents damage from impacts or environmental factors and stops foreign materials from penetrating the installations.

Protective mesh can greatly improve wall resistance against seismic forces. By evenly distributing pressure and forces across the wall surface, it substantially reduces the likelihood of collapse or cracking during strong tremors.

Protective mesh reduces the need for heavy and expensive materials in walls. By creating a strong structural framework, it allows for thinner walls and optimized material consumption without compromising quality or strength.

Protective mesh enhances wall strength and resistance against external forces such as earthquakes and impacts, preventing cracks and damage.

It protects pipes and equipment installed within walls, acting as an insulator to block foreign material infiltration.

Use of protective mesh reduces heavy material requirements, resulting in stronger and lighter walls without sacrificing structural quality.

The mesh contributes to wall stability under seismic forces by distributing pressure uniformly, lowering the risk of collapse and damage.

This guideline covers design and application methods for glass fiber mesh-reinforced mortar to enhance the strength and stability of block walls. Using glass fiber mesh ensures uniform stress and force distribution on walls, preventing cracks and potential damage. This mortar application method not only strengthens the wall structure but also improves resistance to earthquakes and other lateral forces. Adhering to these guidelines increases durability and safety in construction projects.

Silice Ara produces various dry construction mortars such as block adhesives, thin-layer, and thick-layer mortars. These products facilitate and accelerate construction, increase strength, and provide thermal and acoustic insulation. They offer excellent adhesion, crack resistance, and reduce material wastage.

Silice Ara’s U-shaped clamps are engineered for connecting walls to steel and concrete structures as well as ceilings. These clamps bear heavy loads, strengthen structures, reduce costs, and are used in industrial and residential projects.

Silice Ara, relying on modern technologies and high-quality raw materials, supplies autoclaved lightweight Sillex blocks to the market. These blocks, featuring low weight, thermal and acoustic insulation, high fire resistance, and long durability, have quickly gained a prominent position in the construction industry. Their use reduces the dead load of buildings, improves structural performance, and accelerates project execution, making them an ideal choice for contractors and engineers.